Ünnepi nyitvatartás

December 23. - Január 3. között leltár miatt szaküzletünk zárva tart!

Első munkanap: Január 4.

Kellemes ünnepeket kívánunk minden ügyfelünknek és partnereinknek!

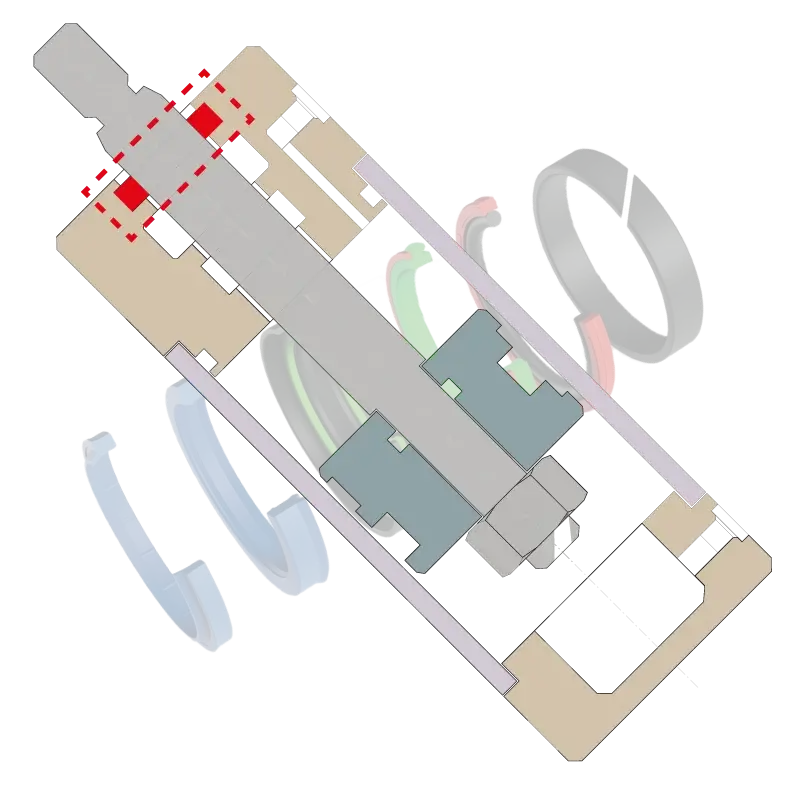

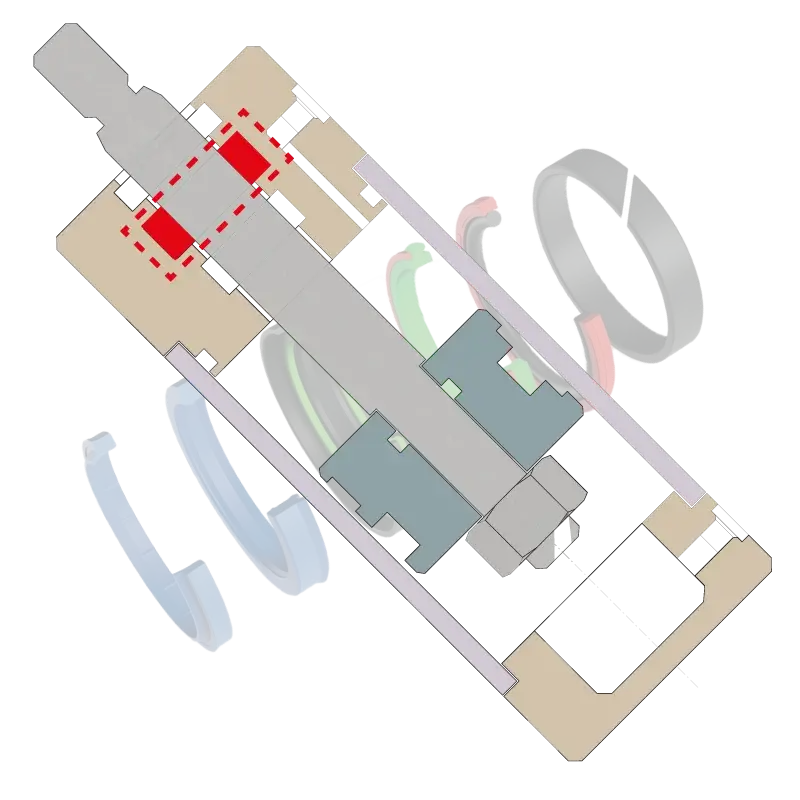

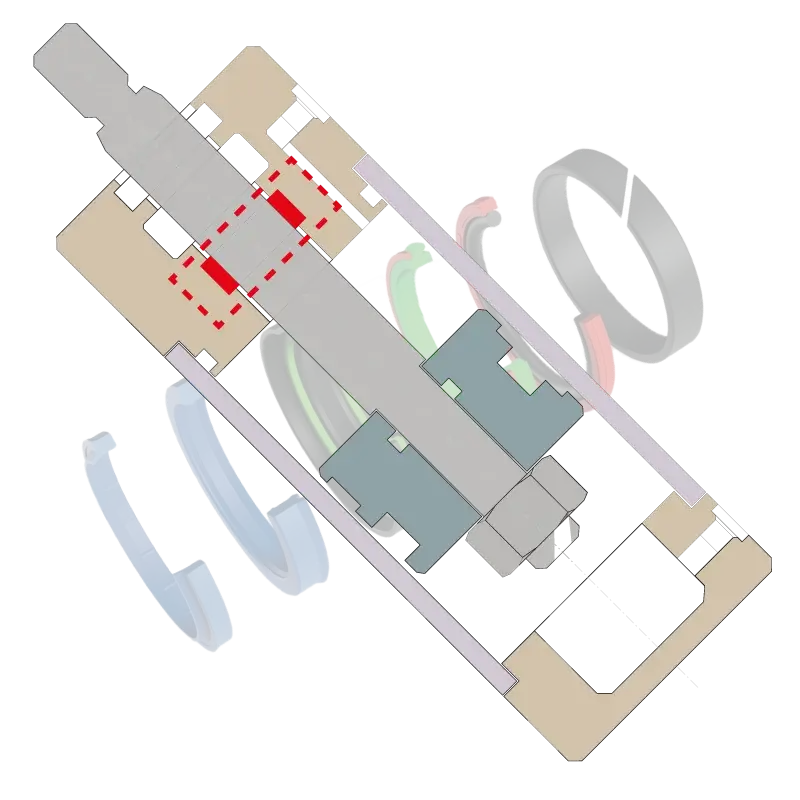

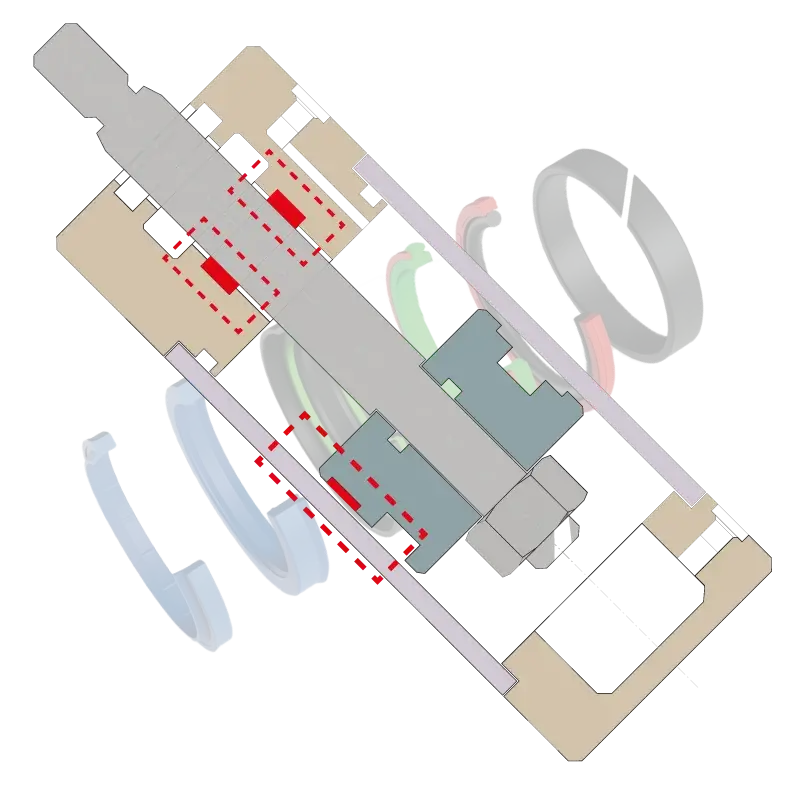

HIDRAULIKA TÖMÍTÉS

Szennylehúzó, szártömítés, szimmetrikus horonygyűrű, sortömítés, vezetőgyűrű, vezetőszalag, dugattyútömítés

SZENNYLEHÚZÓK

Raktáron

SZÁRTÖMÍTÉSEK

Raktáron

VEZETŐGYŰRŰK

Raktáron

VEZETŐSZALAGOK

Raktáron

DUGATTYÚTÖMÍTÉSEK

Raktáron

Gyakran ismételt kérdések

Hol tudom megrendelni a hidraulikatomites.eu oldalon található termékek egyikét?

A hidraulikatomites.eu oldalon található termékeket a

Hidraulika Szaküzlet forgalmazza.

Akár

e-mailben a

címen,

telefonon a +36 (1) 278 2303-mas telefonszámon

vagy személyesen a

1211 Budapest Duna lejáró 8.

címen tudja felvenni velünk a kapcsolatot.

Személyesen is megtekinthető / átvehető egy adott termék?

A Hidraulika Szaküzletben megtekinthetőek a

termékek és rendelés esetén átvehető is.

Sok éves

tapasztalattal rendelkező kollégáink készséggel állnak az ügyfelek

rendelkezésére. Címünk:

1211 Budapest Duna lejáró 8.

Rendelés esetén lehet szállítást is kérni a termékhez?

Lehetőség van a következő munkanapi kézbesítésre, amennyiben délig

megkapjuk a rendelést.

A szállítási lehetőségek súly és

térfogatfüggők. A szállítási díjat és időt az adott rendelési

csomag paramétere határozza meg.

Mit jelentenek pontosan a raktárról elérhető és rendelhető külső raktárról feliratok?

Raktárról elérhető felirattal jelöljük azokat a

termékeket, amellyeket állandó mennyiségben tartunk raktáron, így

azonnal vagy 4-6 munkanapon belül tudjuk kínálni.

A rendelhető külső raktárról felirattal jelölt

termékeket nem tartjuk nagy mennyiségben szaküzletünkben, így

rendelés esetén 1-2 héten belül tudjuk kínálni.

Magánszemélyek is vásárolhatnak Önöknél?

Csak cégek és egyéni vállalkozók kiszolgálása lehetséges nálunk.

Milyen fizetési lehetőségek vannak Önöknél?

Fizethet készpénzzel vagy akár bankkártyával szaküzletünkben. Banki előreutalásra is van lehetőség díjbekérő kiállítása után.

Méretre vágásra, darabolásra van lehetőség?

A szálanyagok esetében a kívánt méretre vágjuk a darabot.

Árajánlat kérés

Kitöltési segédlet

Az árajánlat kéréshez szükséges a kötelező mezők kitöltése.

A kötelező mezők nem maradhatnak üresen.

Cégnév: Minimum 3 karakter. Csak betűk és számok. (opcionális)

Név: Minimum 3 karakter. Csak betűk. (kötelező)

Telefonszám: 7-11 karakter. Csak számok, előjelek nélkül. (kötelező)

E-mail cím: pelda@pelda.hu (kötelező)

Üzenet Minimum 3 karakter, maximum 1500. (kötelező)

Elérhetőségek

Címünk:

Hidraulika Szaküzlet

1211

Budapest Duna lejáró 8.

Telefonszámaink:

Szaküzlet telefonszám:

+36 (1) 278 2303

Ügyeleti telefon: +36 30 884 3170

Tömítés

részleg: +36 70 393 0451 | +36 70 393 0458

E-mail címünk:

Nyitvatartásunk:

H-P 07:00 - 17:00

Sz-V

ZÁRVA

Ügyelet:

H-P 17:00 - 20:00

SZ-V 08:00 - 17:00